- Best Phone:

0755-29750001

2020-07-14

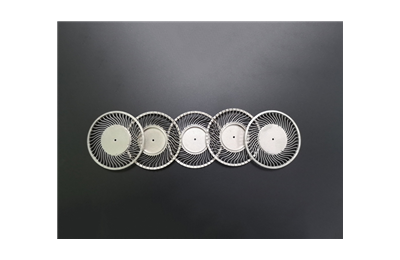

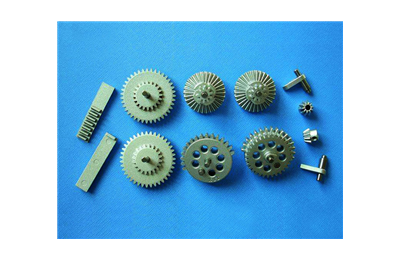

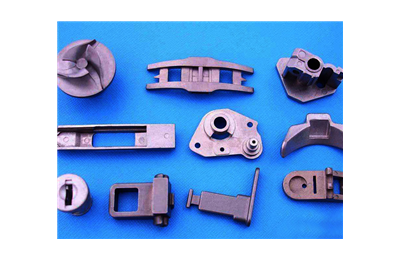

MIM技术的制程技术、材料和设备在国内已经越来越成熟,应用范围也很广。MIM技术的优势在于零件形状复杂、尺寸较小以及产量大。MIM技术这些优势使其在电子数码产品、轻武器、MIM智能穿戴、手工工具、MIM通讯医疗、MIM汽车零件、电子密封件、切削工具及运动器械中得到了大量的应用。 那么,如何判定一个产品是否应该选择……

2020-07-10

深圳市贝斯特精工发现大部分不锈钢MIM材料零件的处理,都使用了不锈钢喷砂工艺处理。那么什么叫喷砂工艺呢?喷砂工艺指的是采用压缩空气为动力,以形成高速喷射束将喷料(铜矿砂、石英砂、金刚砂、铁砂、海南砂)高速喷射到需要处理的工件表面,使工件表面的外表面的外表或形状发生变化。 下面由深圳市贝斯特精工小编简述不锈钢喷……

2020-07-06

金属粉末注射成型(MIM)作为一种新型的加工成型技术,金属粉末注射成型(MIM)的发展受到几个关键因素的影响,这些因素决定了金属粉末注射MIM技术的发展前景、发展速度和发展趋势。这些因素研究得好,可以促进金属粉末注射成型(MIM)的进一步发展,解决得不好会成为其发展的阻力。 金属粉末注射成型(MIM)技术的……

2020-06-29

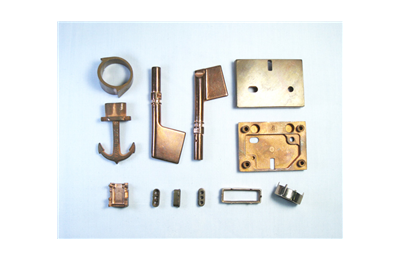

In recent years, powder metallurgy scholars have paid more attention to materials with "nano" and "composite" characteristics, while ignoring the expanding role of basic materials and their processes in the field of powder metallurgy. Shenzhen Best found that copper has played a big role in the field of powder metallur……

2020-06-24

Metal powder injection molding (MIM) as a new type of processing molding technology, the development of metal powder injection molding (MIM) is affected by several key factors, these factors determine the development prospects, development speed and development of metal powder injection MIM technology trend. Well-studi……

2020-06-22

Powder metallurgy high-speed steel refers to the fine high-speed steel powder obtained by atomizing high-speed molten steel with high-pressure inert gas or high-pressure water, and then pressed and formed under high temperature and high pressure, and then sintered. New developments in Shenzhen Best Precision Powder Met……

2020-06-18

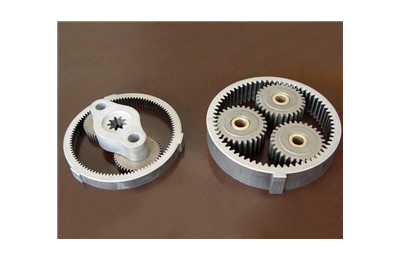

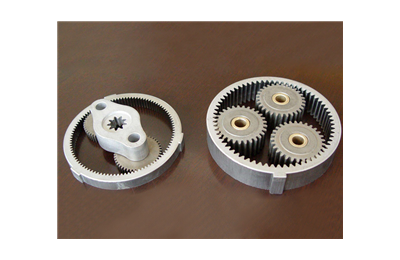

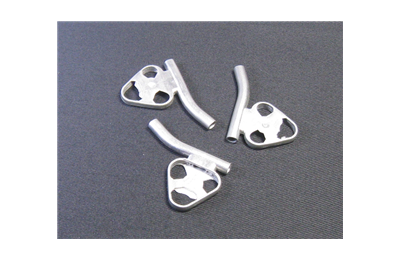

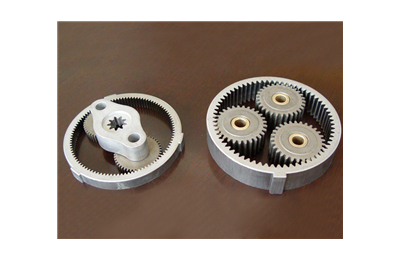

Metal powder metallurgy injection molding (MIM) technology is a comprehensive and interdisciplinary product that integrates plastic molding technology, polymer chemistry, powder metallurgy technology and metal materials science. The mold can be used to inject blanks and quickly manufacture high The structural parts wit……

2020-06-18

In the process of understanding the powder metallurgy technology, Shenzhen Best has come into contact with the metal powder injection molding process. I did not expect it to be completely different from the ordinary molding technology. It manufactures MIM ceramic watches with complex geometric shapes, high performance ……

2020-06-12

Metal powder injection molding technology is a product of multi-disciplinary and cross-cutting of plastic molding technology, polymer chemistry, powder metallurgy technology and metal materials science. The mold can be used to inject blanks and quickly produce high density and high precision through sintering. 3. Three……

2020-06-10

The main reason for the under-injection is that the flow resistance is too large, which prevents the melt from continuing to flow. Factors affecting the melt flow length include: part wall thickness, mold temperature, injection pressure, melt temperature and material composition. These factors can cause short bets if n……

2020-06-08

The gate, also known as the feed port, is a channel connecting the runner and the melt in the cavity. The proper choice of gate is directly related to whether the metal powder injection molded products are intact and injection molded with high quality. Gate design includes: 1. Determination of gate cross-sectional shap……

2020-06-04

Damascus steel, modern refers to steel with a pattern on the surface. The traditional Damascus steel is mainly divided into two types according to the cause: The first is cast-type Damascus steel, also known as Uz steel, which was produced in ancient India and its texture was crystallized during the casting process. No……

Copyright: Shenzhen Best Precision Technology Co., Ltd.|Metal powder injection molding factory, manufacturer, customized company, supplier, process parts 粤ICP备18054342号